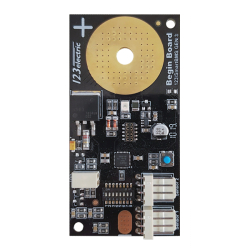

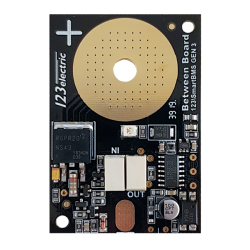

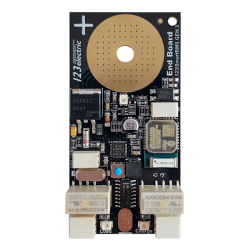

123electric 123ELECTRIC BMS123 Smart Gen3 - Complete Set (4 Cells) With Bluetooth 4.0

Art.#:

BMS123SM-G3-SET

Manufacturer:

123electric

To order

This article is discontinued. Please, chose another one!!!

GWL/Power BMS123 Smart Gen 3 – a complete solution for LFP, LTO, NMC and Li-Ion cells to make battery with Bluetooth monitoring and management using your smart phone, iPad, tablet or other device.

English

English Česká republika

Česká republika Germany

Germany France

France España

España Italia

Italia Sverige

Sverige Polski

Polski Nederland

Nederland